Manage lots of identical products¶

Lots are useful for products you receive in great quantity and for which a lot number can help in reporting, quality controls, or any other info. Lots will help identify a number of pieces having, for instance, a production fault. It can be useful for a batch production of clothes or food.

Flectra has the capacity to manage lots, ensuring compliance with the traceability requirements imposed by the majority of industries.

The double-entry management in Flectra enables you to run very advanced traceability.

Setting Up¶

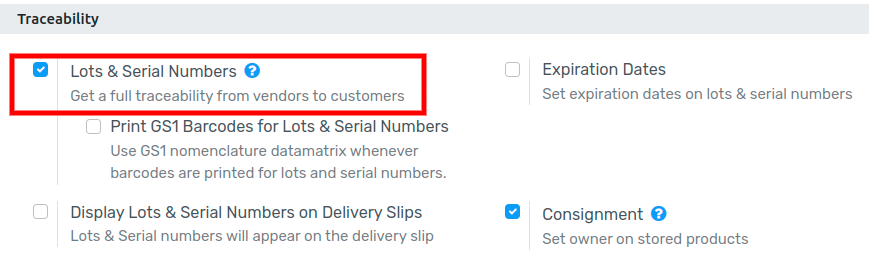

Application Configuration¶

First, you need to activate the tracking of lot numbers. To do so, go to and tick Lots & Serial Numbers. Then, click on save.

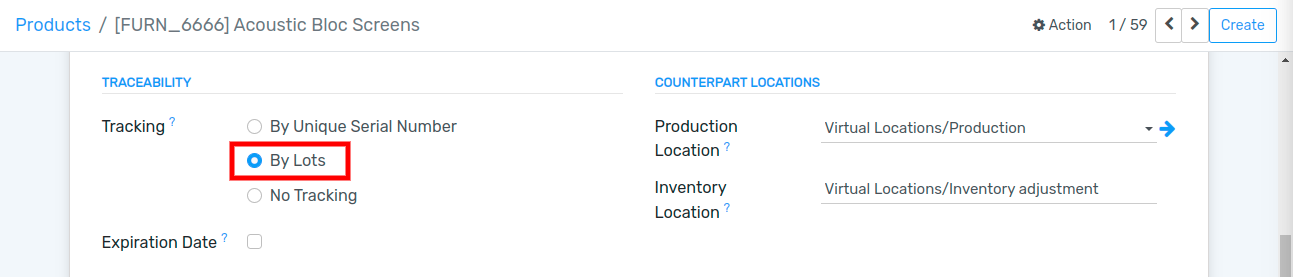

Product Configuration¶

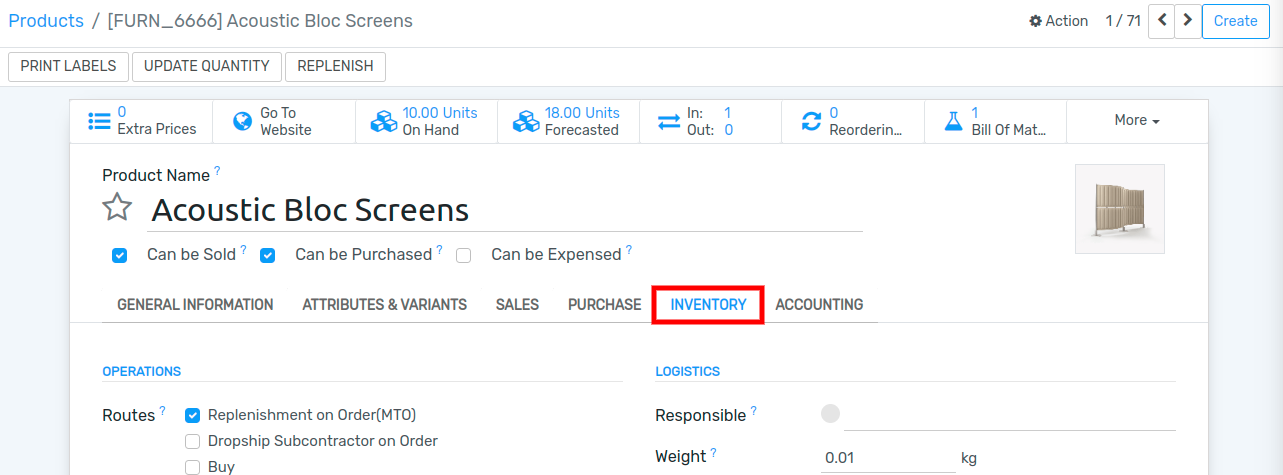

Now, you have to configure which products you want to track by serial numbers.

Go to and open the product of your choice. There, click on Edit and select Tracking by Lots in the inventory tab.

Manage Lots¶

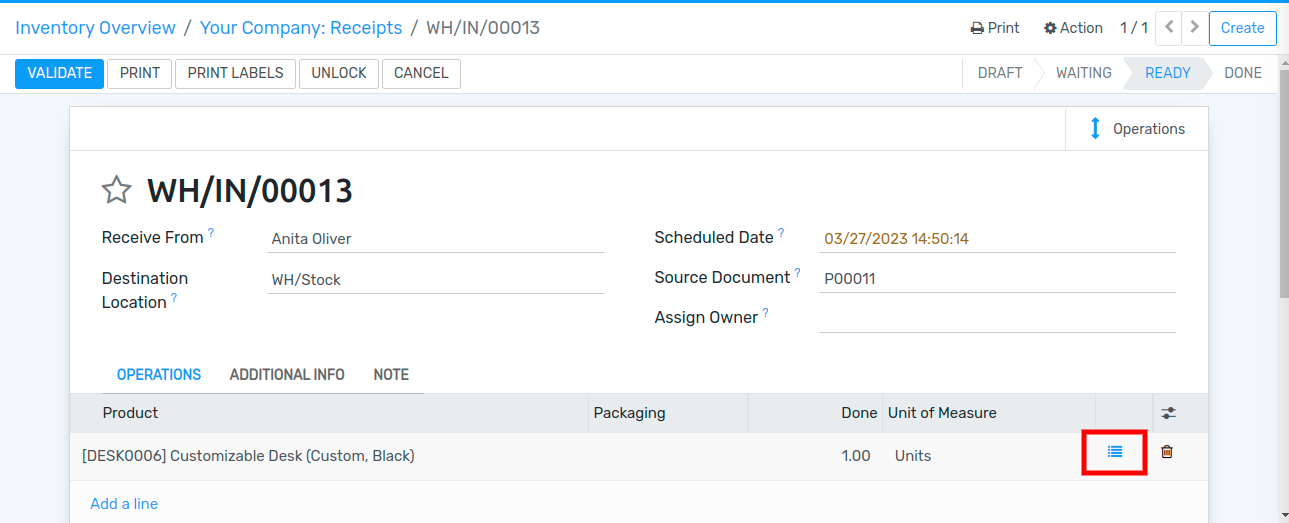

Receipts¶

In order to receive a product tracked by lots, you have to specify its lot numbers. You have several ways of doing so:

Manually assign the different lot numbers

Copy/paste lot numbers from an Excel file

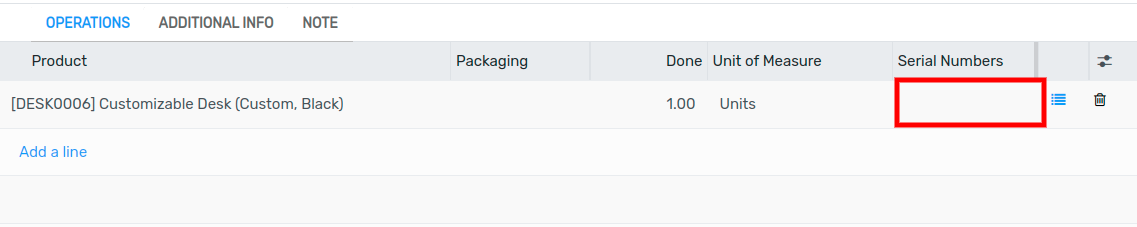

First, you need to open the detailed operations of your picking.

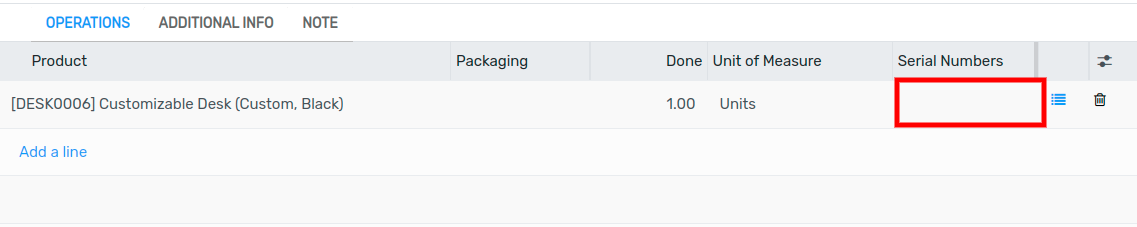

Manually assign the different lot numbers¶

When opening the detailed operations, you can click on Add a line. Then, you will be able to fill the lot number in. Once done, you can click on Add a line again to register a new lot number.

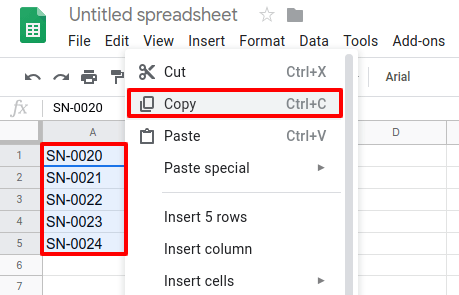

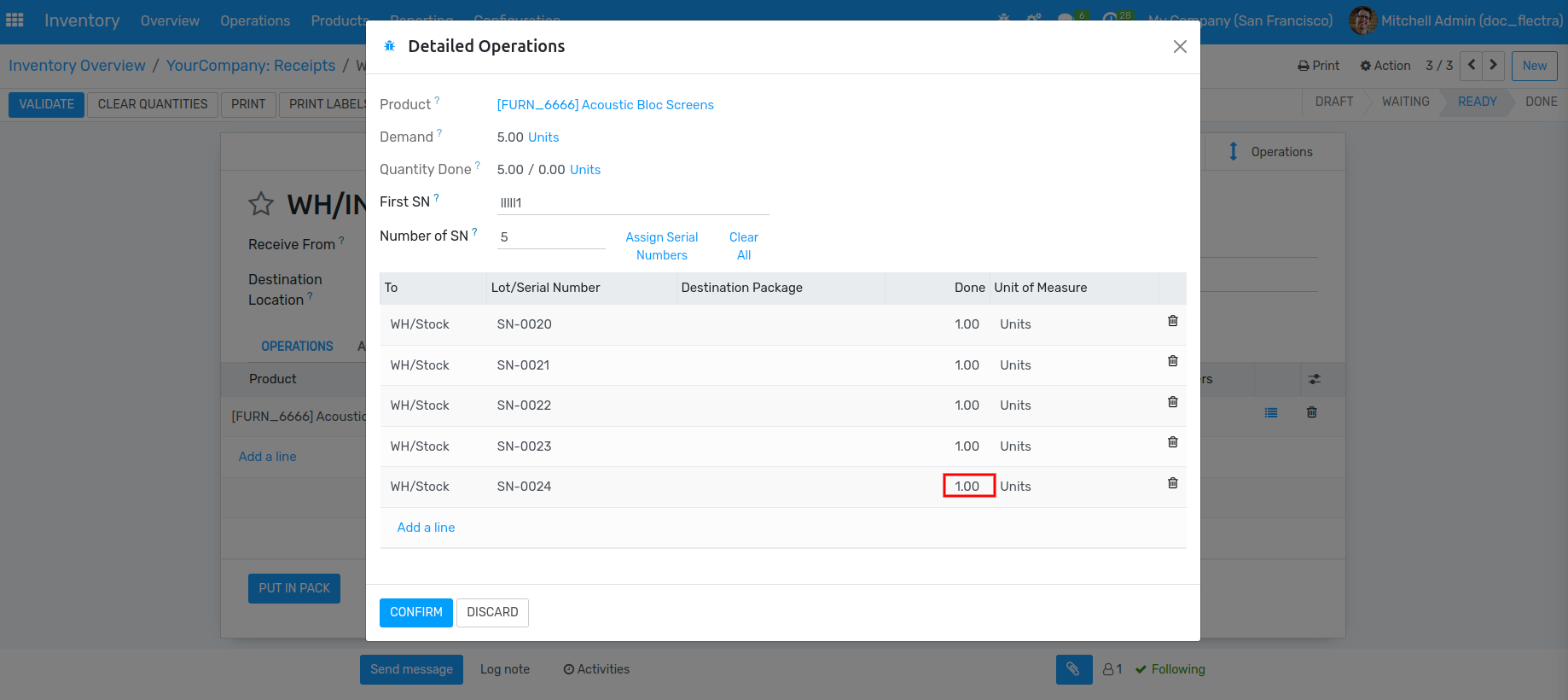

Copy/paste lot number from an Excel file¶

Once the spreadsheet containing the lot numbers you received from your supplier and copy the list. Then, you can paste them in the Lot/Serial Number Name column for Flectra to automatically create the necessary lines. After that, you will have to manually enter the number of products that are contained in each one of the lots.

Operation Types¶

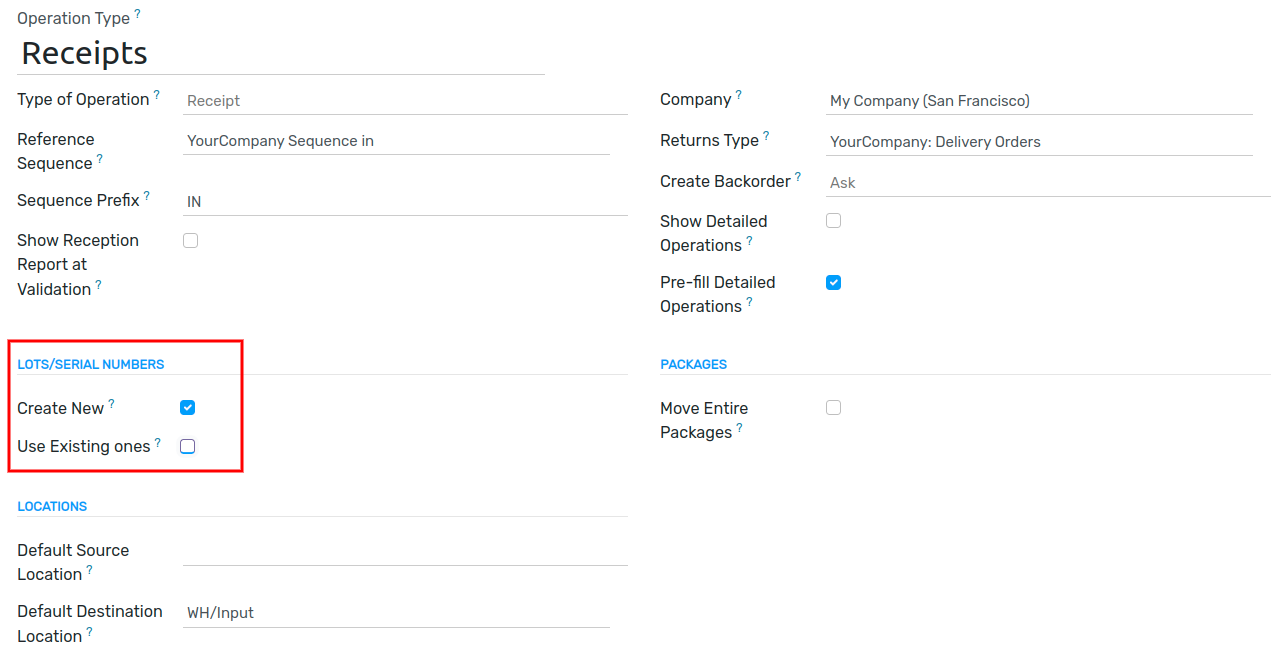

Of course, you also have the possibility to define how you will manage lots for each operation type. To do so, open the Inventory app and go to .

For each type (receipts, internal transfers, deliveries, …), you can decide if you allow to create new lot numbers or only use existing ones. By default, the creation of new lots is only allowed at product reception, and using existing lot numbers isn’t allowed in this operation. If you have inter-warehouse transfers and track products by lots, it can be useful to allow using existing lot numbers in receipts too.

Lots traceability¶

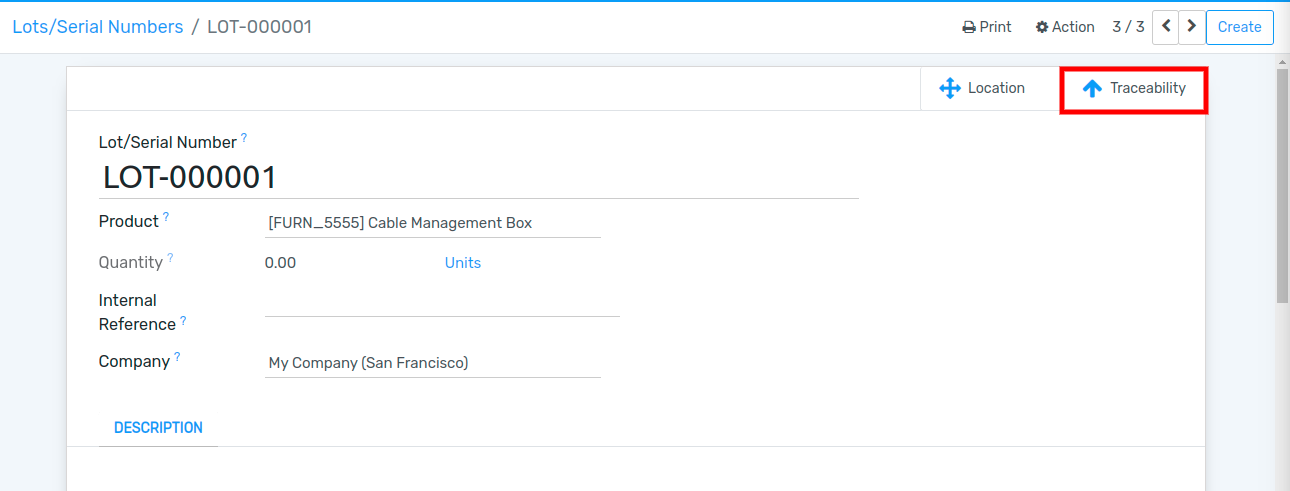

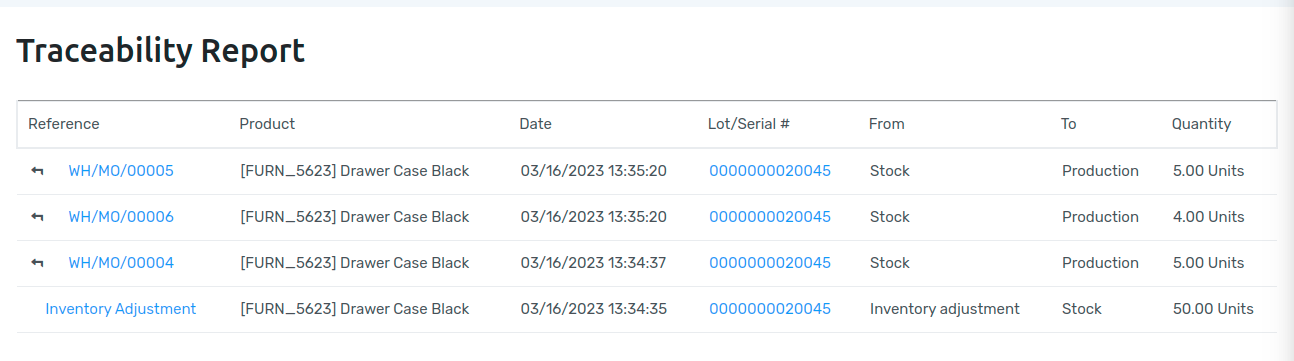

The lot number given to the products allows you to keep track of where they were received, put in stock, to whom they were sold and where they were shipped to.

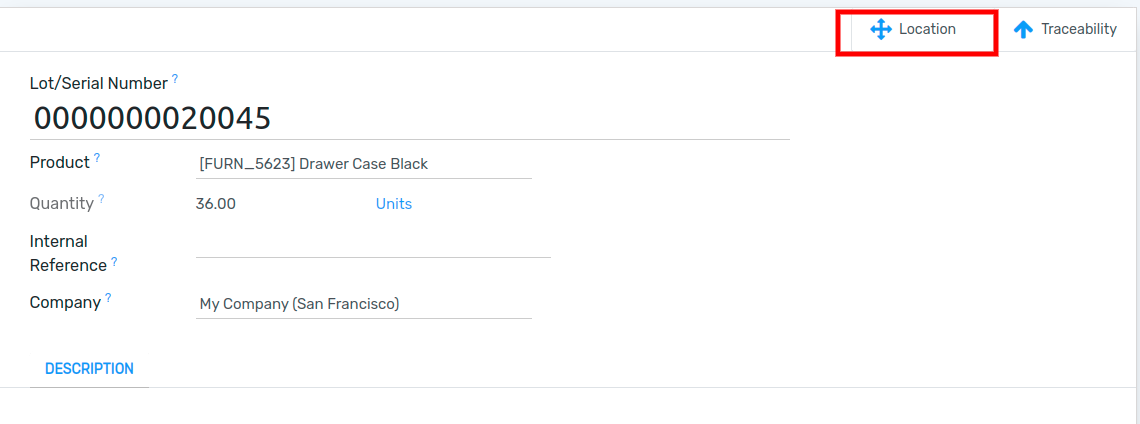

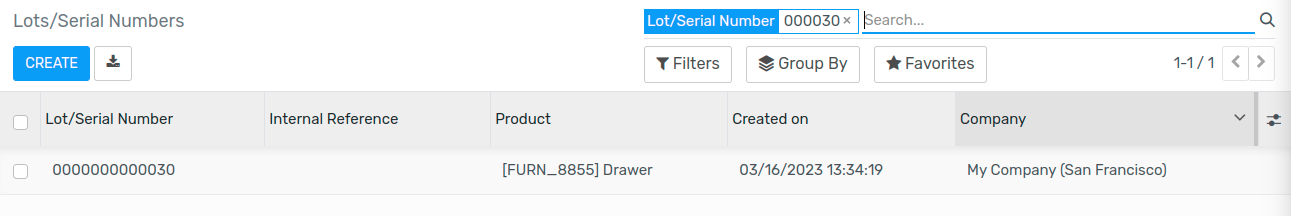

To track an item, open the Inventory module and, in , click on the lot number corresponding to your search.

When you open the Traceability information, you see in which documents the lot number has been used.

Now, if you want to locate the lot number, you can do so by clicking on the Location stat button.