Add quality controls¶

Use Flectra Quality to control the quality of products before they are registered into stock, during picking operations, and when leaving the warehouse for a delivery order. By creating quality control points, manufacturers can set up quality checks that automatically trigger at specific points during production.

Configure quality control points¶

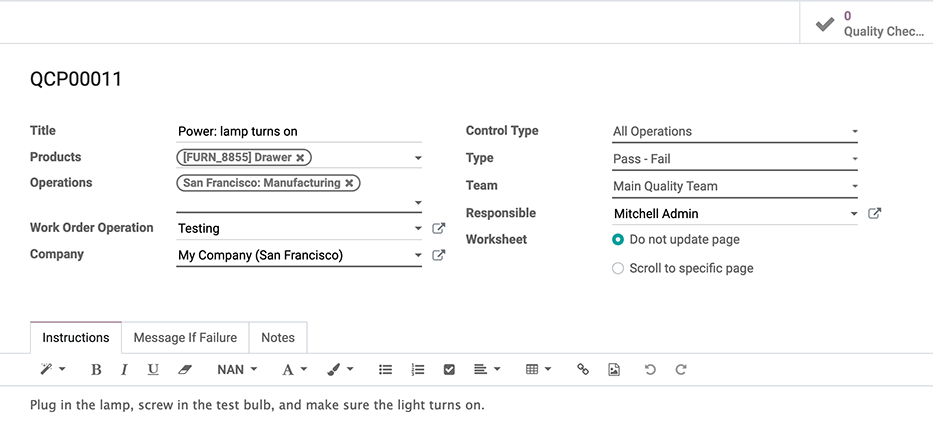

To create a new quality control point, go to . Then, fill in the following form fields, accordingly:

Title: give the quality control point a simple, but informative title so production floor and quality check teams can understand it easily

Products: indicate which product(s) should pass through the specific quality control point

Operations: determine which operations team(s) should perform the quality control check (e.g.,

Manufacturing,Receipts,Delivery Orders, etc.)Work Order Operation: for manufacturing operations, use the drop-down menu to indicate which type of work order the quality control point applies to: Manual Assembly, Packing, Assembly, Testing or Long time assembly

Company: add the company that will implement the quality control point. Usually this will be the company that owns the Flectra database. However, a multi-company or vendor profile can be selected, as well, for cases where there are multiple manufacturing or engineering locations

Control Type: using the drop-down menu, choose from All Operations, Randomly or Periodically to determine how often the control point should executed

Type: using the drop-down menu, choose the control point type: Instructions, Take a Picture, Pass - Fail, or Measure

Team: decide which quality team should receive the results of the quality control point check

Responsible: add a point person to manage the status and evolution of the quality control point over time

The tabs at the bottom of the form can be used to provide additional information to quality teams:

Instructions: describe the quality check to be performed

Message If Failure: detail what should be done if the check fails

Notes: use to include any additional information

Once a control point has been configured, a quality check will be automatically created and assigned when the specified operation or work order has been reached. Quality checks can be managed by selecting .

Tip

To see all of the quality checks created by a control point, go to , select a control point, and click Quality Checks in the top right corner.

Use case: configure a measure quality check¶

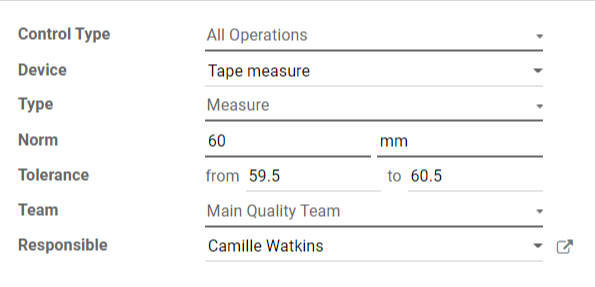

To ensure that a product meets specific measurement requirements, select Measure from the Type drop-down menu. Selecting the Measure quality check type reveals three new fields: Device, Norm, and Tolerance. These fields can be configured so that only products within a certain tolerance will pass the check:

Device: select the measuring device that should be used to take the measurement (e.g., measuring tape).

Norm: specify the desired measurement that the product should conform to and the unit of measurement that should be used

Tolerance: select the range that a measurement can be within while still passing the check (e.g., from 59.5 mm to 60.5 mm)

When the quality control points form is complete, click Save. Now, this measurement-based test will trigger for products that were specified on the form.

When production of the specified product reaches the operation that requires a measure quality check, the manufacturing employee responsible will be prompted to record and validate the measured value in the tablet view. For products that measure within the values indicated in the Tolerance fields, the test will pass. However, for products that measure outside of those values, the test will fail. In that case, the worker who performed the check would create a quality alert from the tablet view. That quality alert can then be addressed by the quality management team.