Process a Receipt in three steps (Input + Quality + Stock)¶

Quality is essential for most companies. To make sure we maintain quality throughout the supply chain, it only makes sense that we assess the quality of the products received from suppliers. To do so, we will add a quality control step.

Flectra uses routes to define how to handle the different receipt steps. Configuration of those routes is done at the warehouse level. By default, the reception is a one-step process, but it can also be configured to have two-steps or three-steps processes.

The three-steps flow works as follows: you receive the goods in your receiving area, then transfer them into a quality area for quality control (QC). When the quality check is completed, the goods that match the QC requirements are moved to stock

Activate Multi-Step Routes¶

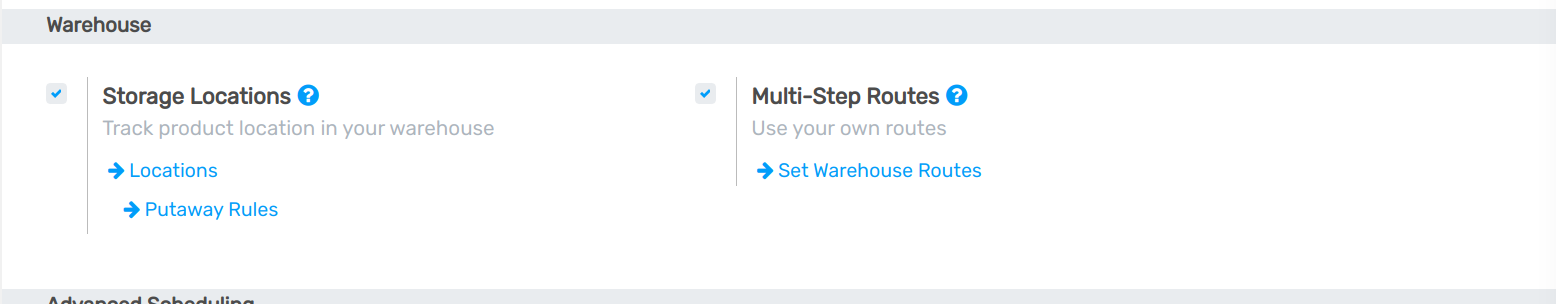

The first step is to allow the use of Multi-Step Routes. Routes provide a mechanism to chain different actions together. In this case, we will chain the picking step to the shipping step.

To enable Multi-Step Routes, go to and activate the option.

Note

By default, activating Multi-Step Routes also activates Storage Locations.

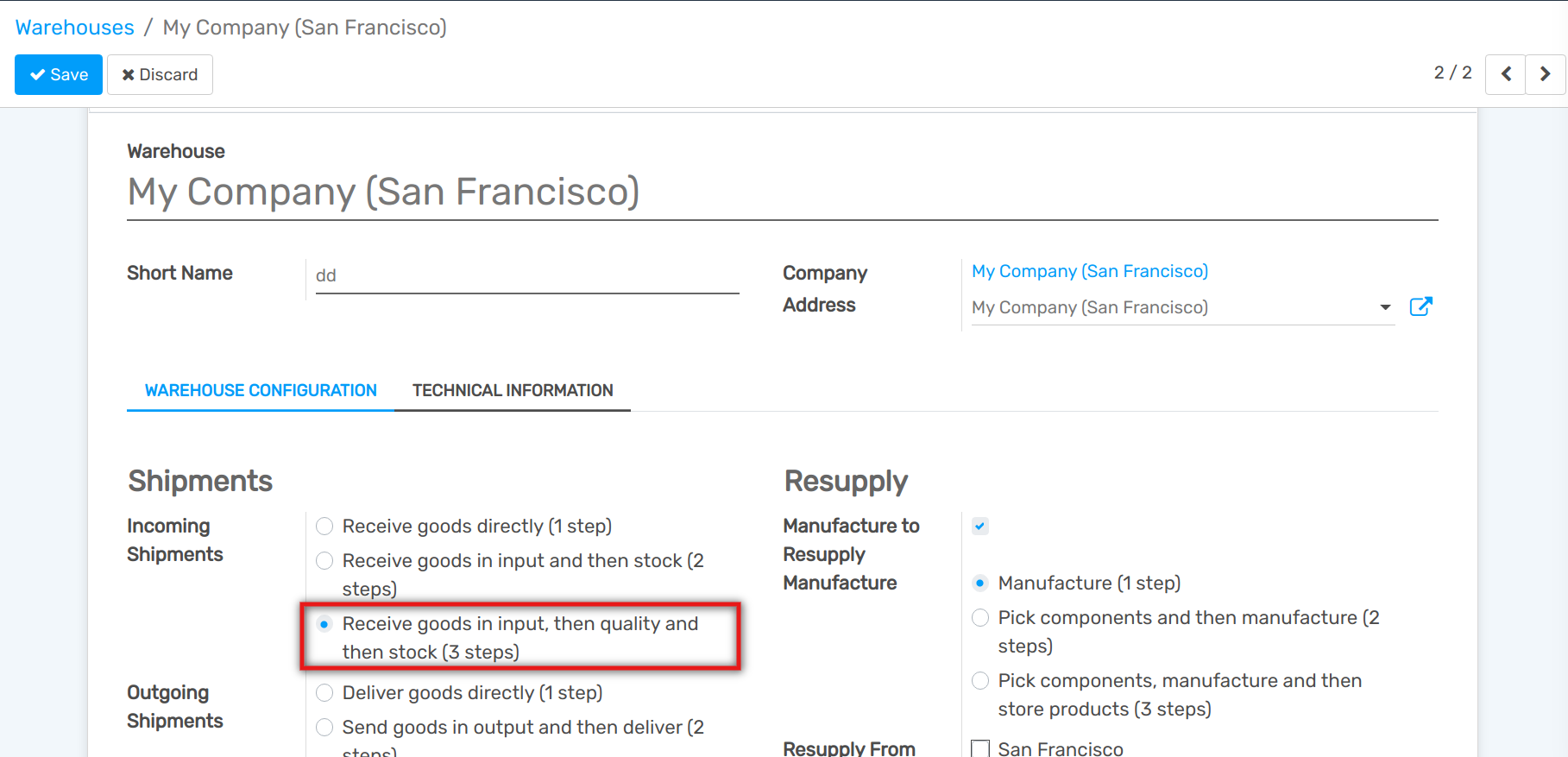

Configure warehouse for receipt in 3-steps¶

Once Multi-Step Routes has been activated, go to and enter the warehouse which should work with the 3-steps reception. Then, select Receive goods in input, then quality and then stock (3 steps) for Incoming Shipments.

Activating this option leads to the creation of two new locations: Input and Quality Control. To rename them, go to and select the one you want to rename.

Create a Purchase Order¶

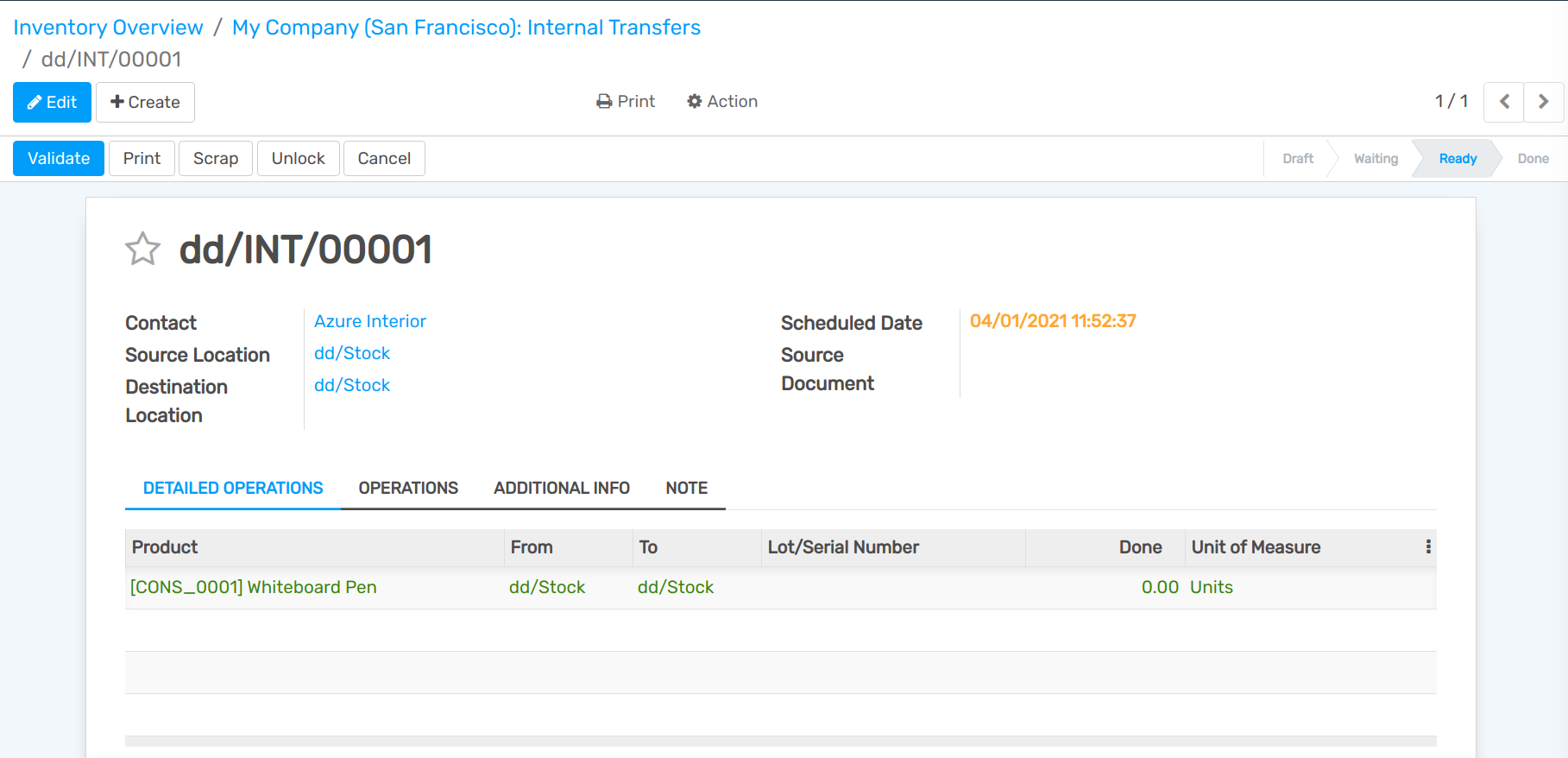

To start the 3-steps reception process, create a Request for Quotation from the Purchase app, add some storable products to it and confirm. Then, three pickings are created with your Purchase Order as the source document:

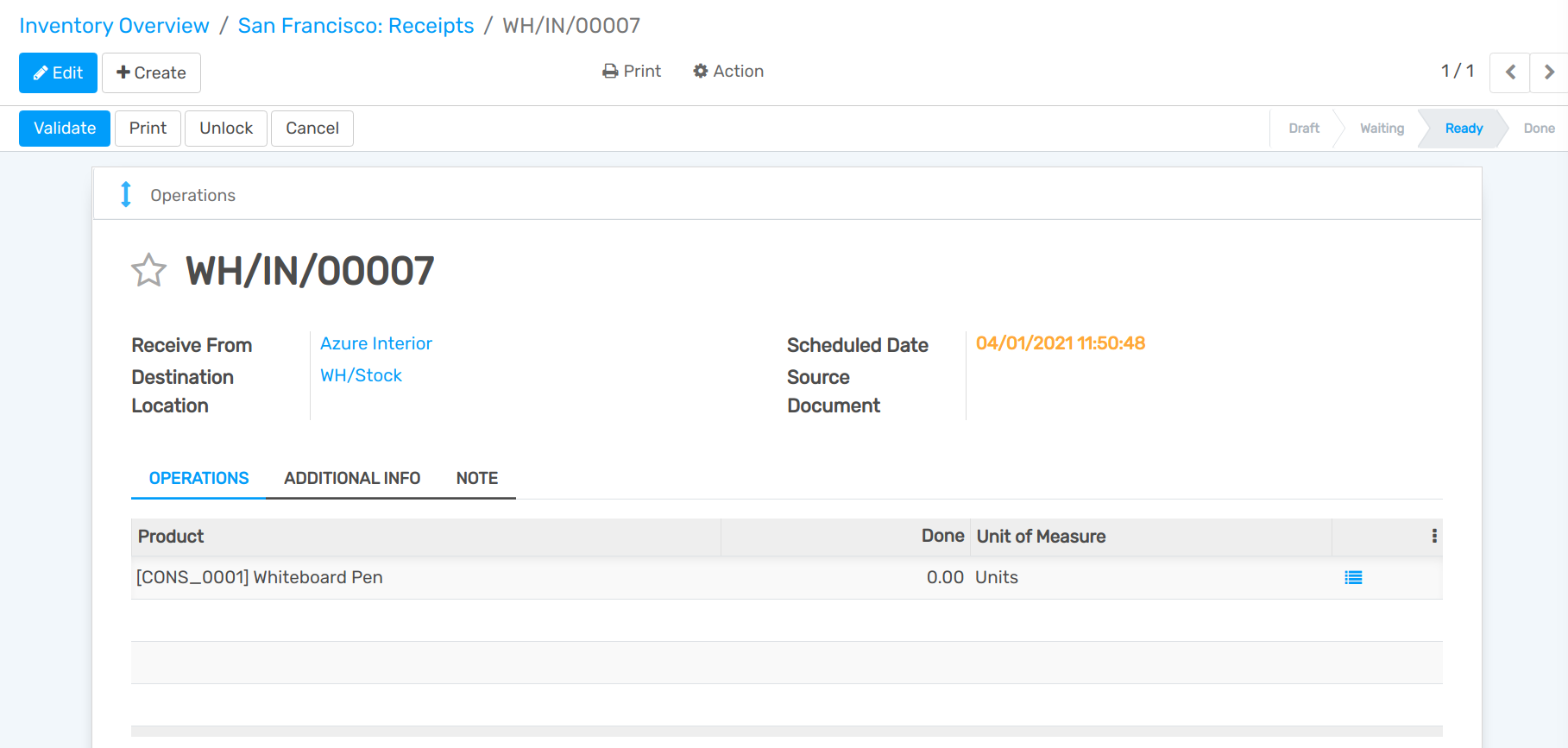

The first one with a reference IN to designate the receipt process;

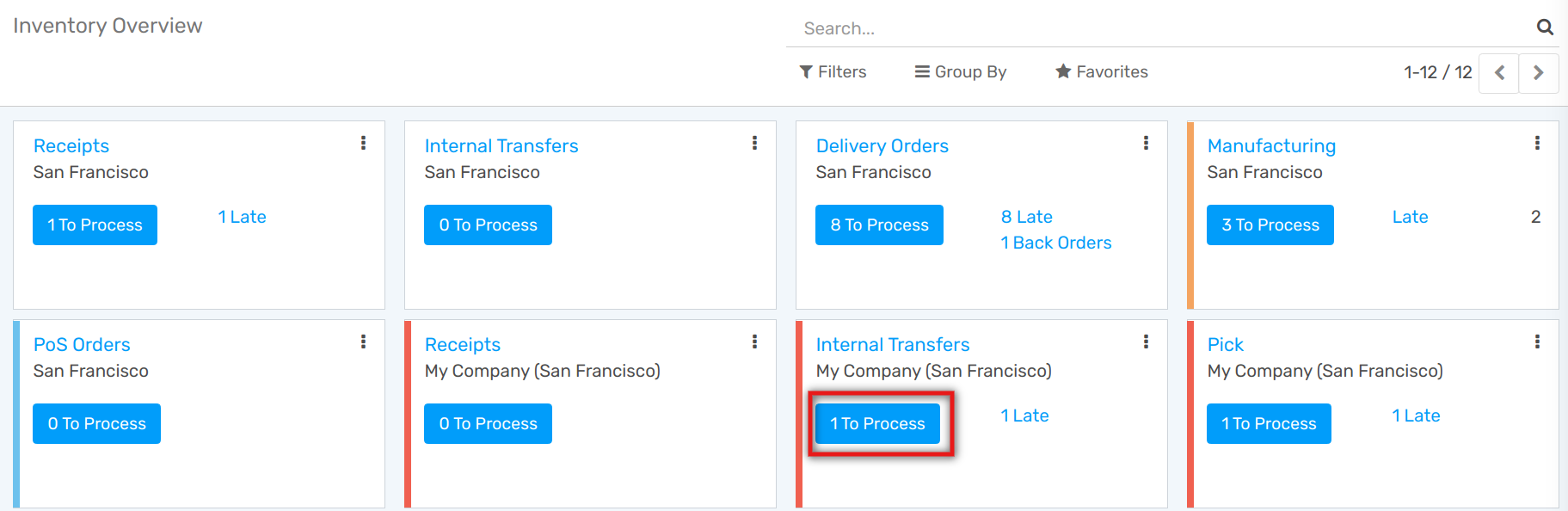

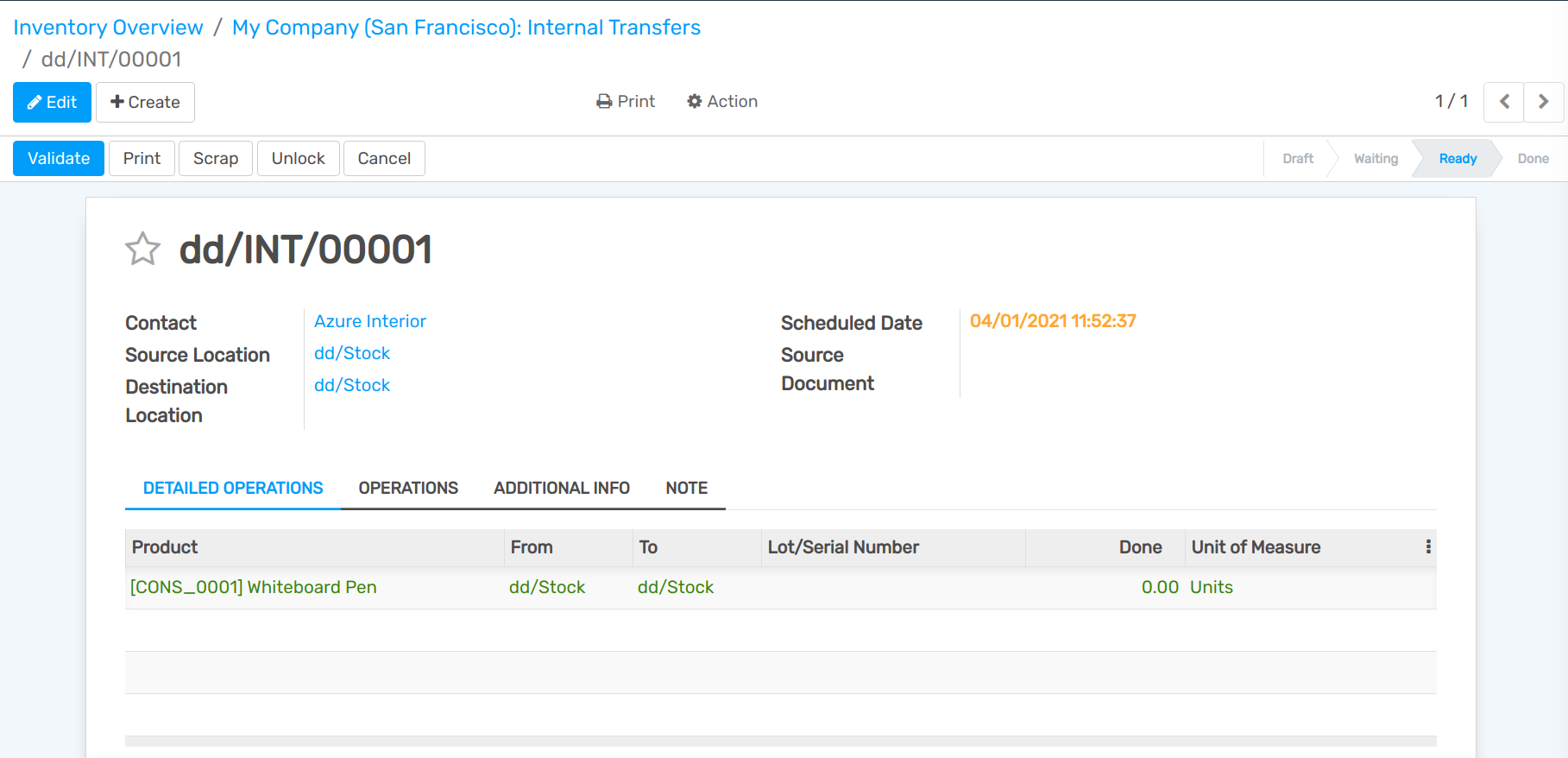

The second one with a reference INT, which is the move to the quality control zone;

The last one with a reference INT to designate the move to stock.

Process the receipt, quality control and entry in stock¶

As the receipt operation is the first one to be processed, it has a Ready status while the others are Waiting Another Operation.

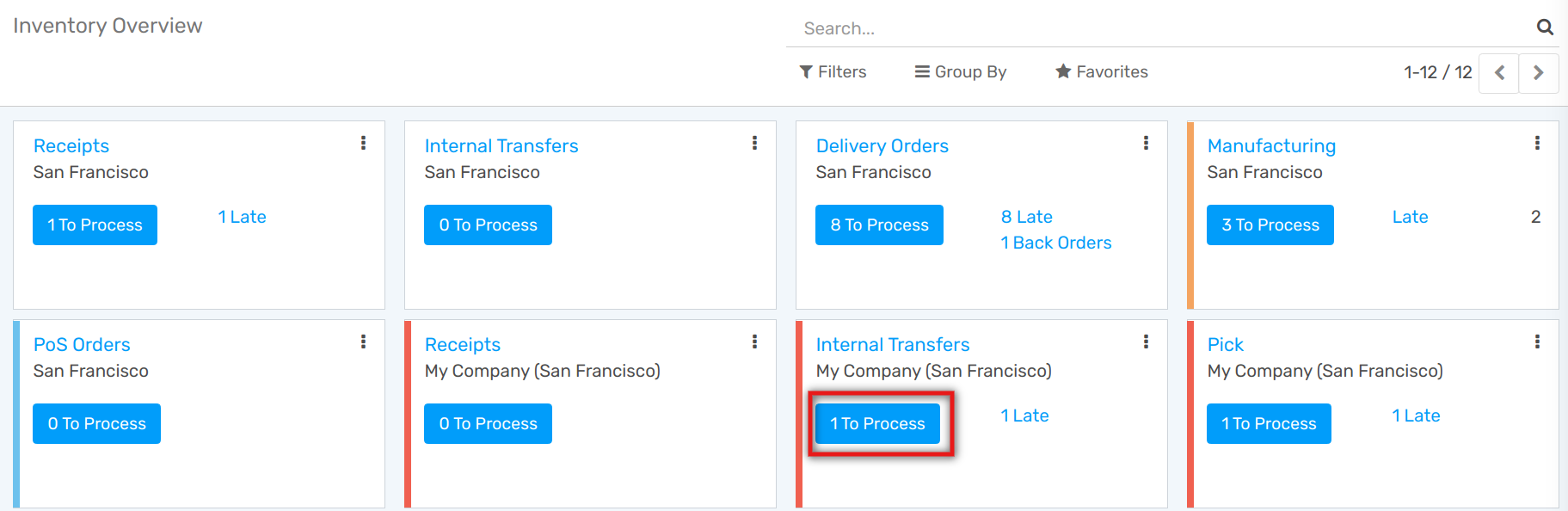

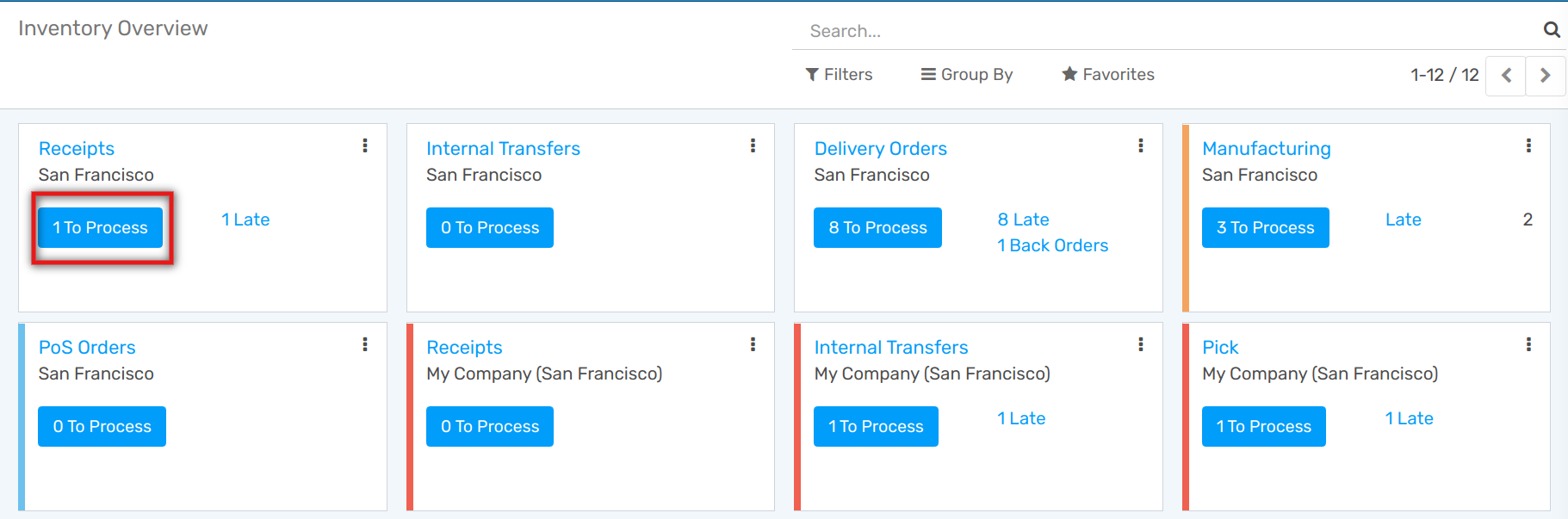

To access the receipt operation, click on the button from the Purchase Order or go back to the Inventory app dashboard and click on Receipts.

In the receipt order, products are always considered available because they come from the supplier. Then, the receipt can be validated.

Once the receipt has been validated, the transfer to quality becomes Ready. And, because the documents are chained to each other, products previously received are automatically reserved on the transfer. Then, the transfer can be directly validated.

Now, the transfer that enters the products to stock is Ready. Here, it is again ready to be validated in order to transfer the products to your stock location.