Manage semi-finished products¶

In Flectra, you can use subassembly products to simplify a complex Bill of Materials or to represent your manufacturing flow more accurately. A subassembly product is a manufactured product that is used as a component to make another one.

A BoM that employs subassemblies is referred to as a multi-level BoM. Those are accomplished by creating a top-level BoM and subassembly ones. This process requires a route that will ensure that every time a manufacturing order for the top-level product is created, another one will be for subassemblies.

Configure the Subassembly Product¶

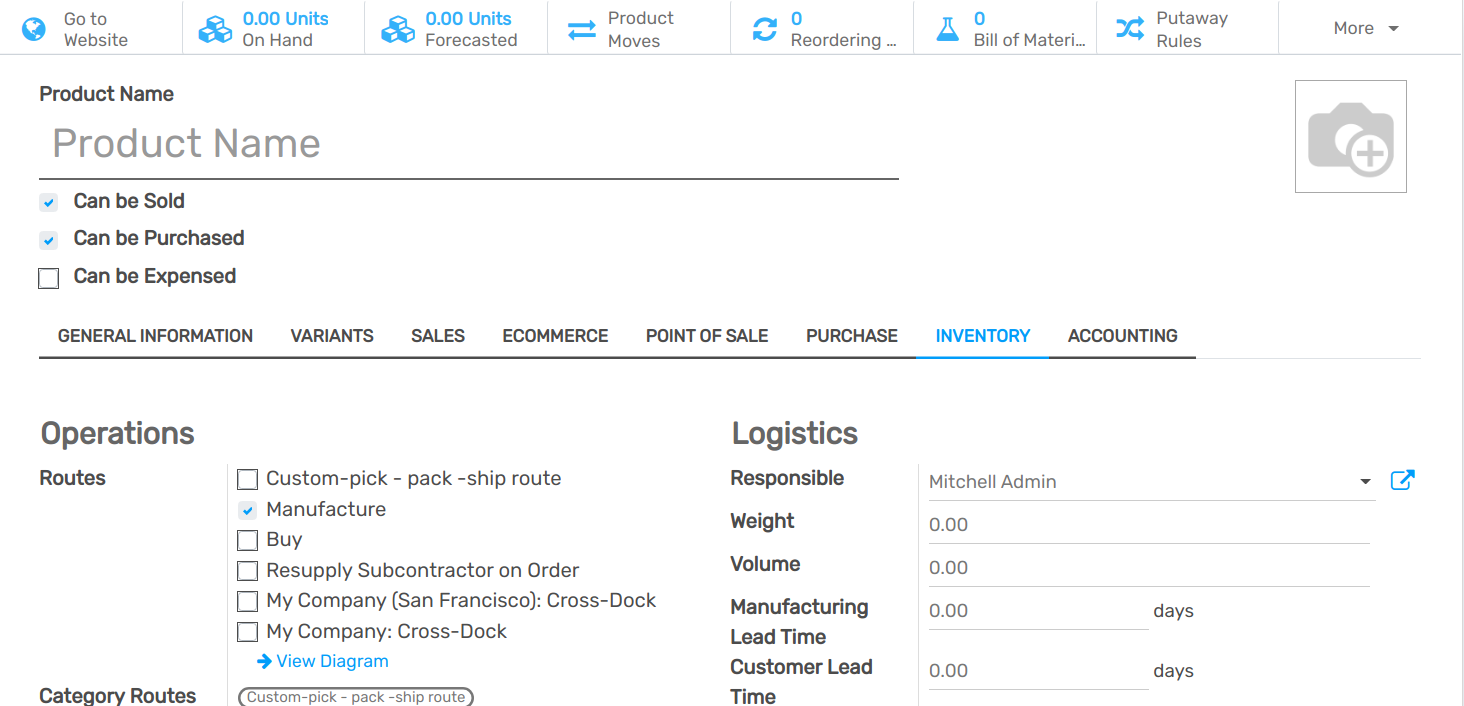

To configure a multi-level BoM, you will need a top-level product but also its subassemblies. The first step is to create a product form for each of the subassemblies. Select the routes Manufacture and Replenish on Order. Now, hit save.

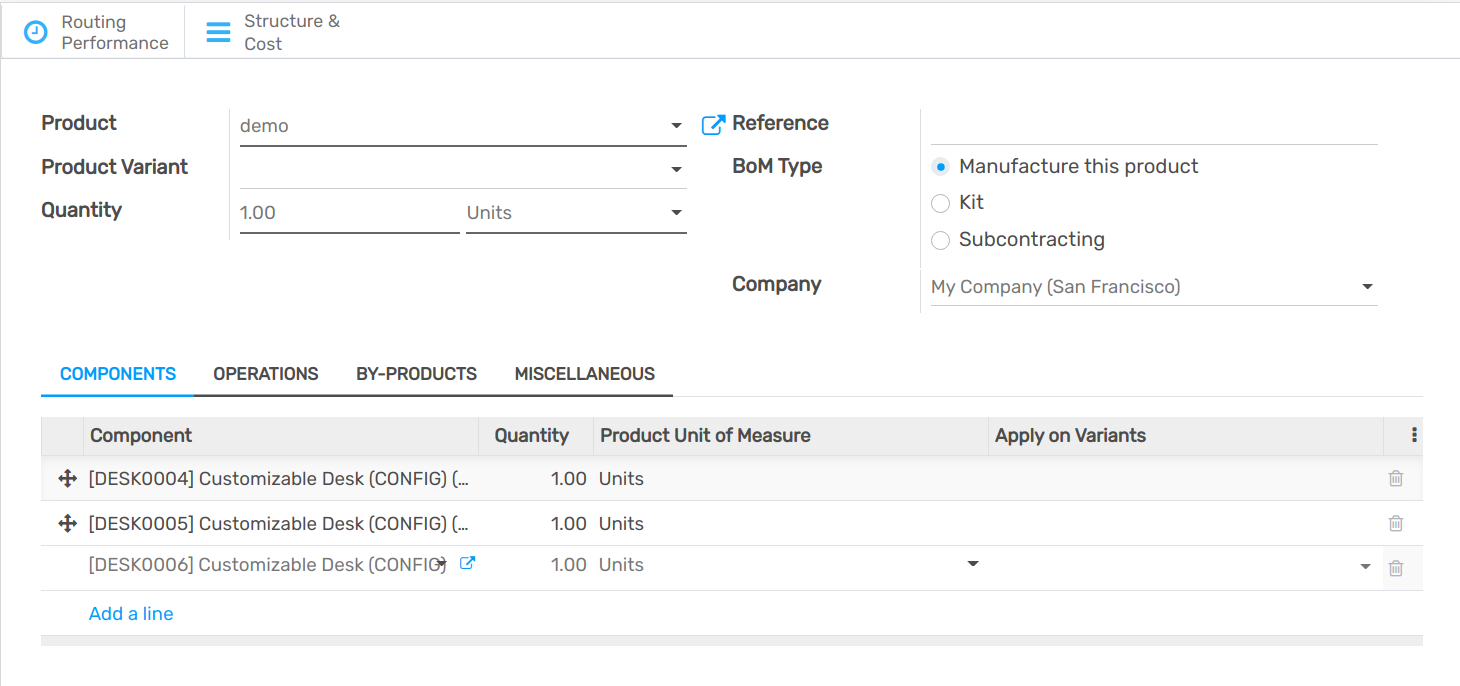

In the Bill of Materials menu, under Master Data, create a new Bill of Materials. Choose the product you just created and add its components.

Configure the Main BoM¶

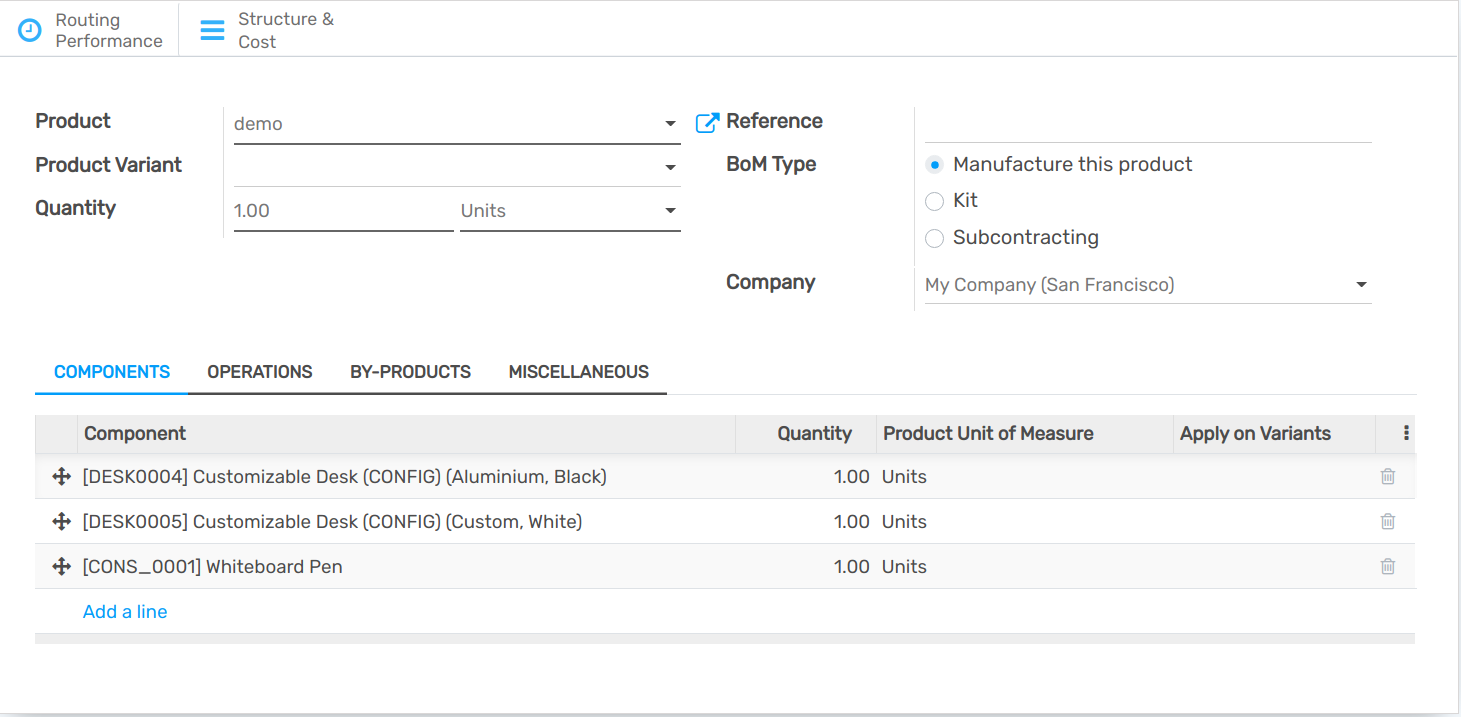

Now, you can configure the top-level product and its BoM. Include any subassemblies in the list of components.

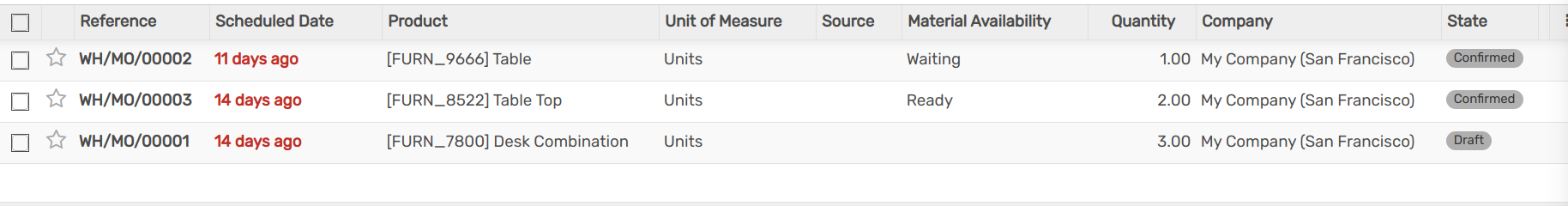

Now, each time you will plan a manufacturing order for the top-level product, a manufacturing order will be created for the subassembly one. Then, you will have to manufacture the subassembly in order to make it available before manufacturing the finished product.