How is the Scheduled Delivery Date Computed¶

Providing the best possible service to customers is vital for business. It implies planning every move: manufacturing orders, deliveries, receptions, and so on. To do so, you need to configure lead time properly and coordinate scheduled dates.

By using lead times, Flectra provides end dates, the Commitment Date, for each process. On a sales order, for example, this is the date your customer will get the products he ordered.

From the customers’ side, the commitment date is important because it gives them an estimation of when they will receive their products. The dates take all other lead times, such as manufacturing, delivery, or suppliers, into account.

How are Lead Times Calculated?¶

As said above, there are several types of lead times. Each is calculated based on various indicators. Before going through the configuration, here is a brief summary of how lead times are calculated and what they are:

Customer Lead Time: the customer lead time is the default duration you set. Therefore, the expected date on the sales orders is today + customer lead time.

Sales Security Lead Time: the purpose is to be ready shipping that many days before the actual commitment taken with the customer. Then, the default scheduled date on the delivery order is SO delivery date - Security Lead Time.

Purchase Security Lead Time: additional time to mitigate the risk of a vendor delay. The receipt will be scheduled that many days earlier to cope with unexpected vendor delays. In case of a Replenish to Order, the Delivery order scheduled date - Security lead time for purchase will be the default Receipt scheduled date.

Purchase Delivery Lead Time: this is the expected time between a PO being confirmed and the receipt of the ordered products. The Receipt scheduled date - Vendor delivery date is the default PO Order By date.

Days to Purchase: number of days the purchasing department takes to validate a PO. If another RFQ to the same vendor is already opened, Flectra adds the line to the RFQ instead of creating a new one. Then, the specific date is set on the line.

Manufacturing Lead Time: this is the expected time it takes to manufacture a product. This lead time is independent of the quantity to produce and does not take the routing time into account.

Manufacturing Security Lead Time: additional time to mitigate the risk of a manufacturing delay. In case of a Replenish to Order, the Delivery Order scheduled date - Manufacturing Lead Time - Manufacturing Security Lead Time is the default Manufacturing Order planned date.

Sales - Lead Times¶

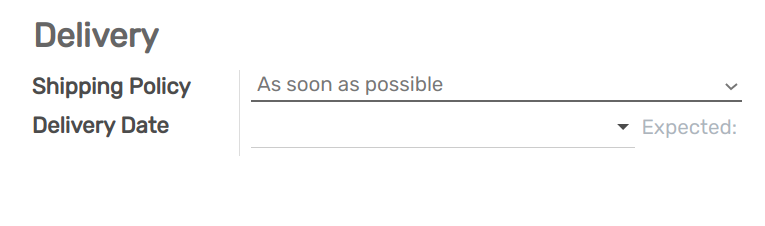

In the Sales app, there is an option called Delivery Date. It allows seeing an additional field on the sales orders, Expected Date. This one is automatically computed based on the different lead times previously configured.

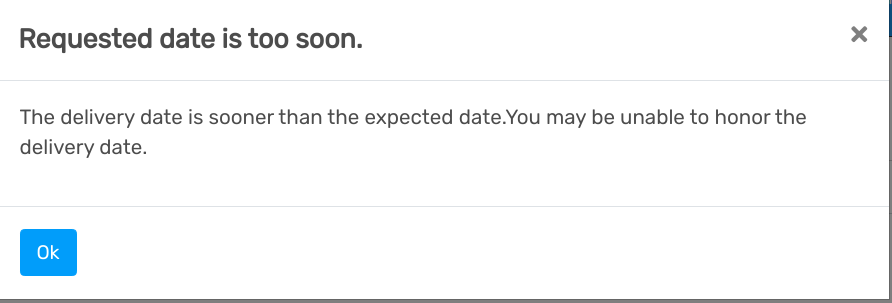

If the set up Delivery Date is earlier than the the Expected Date, a warning message is displayed.

But, for all of this properly working, it is still necessary to configure all the lead times that could occur.

Customer Lead Time¶

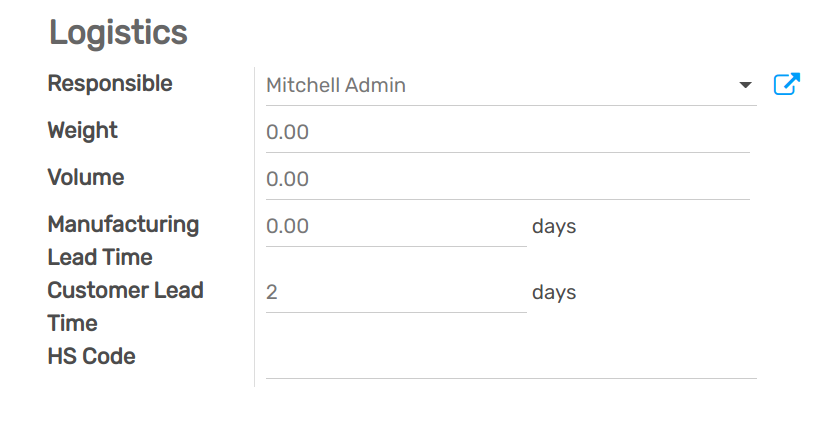

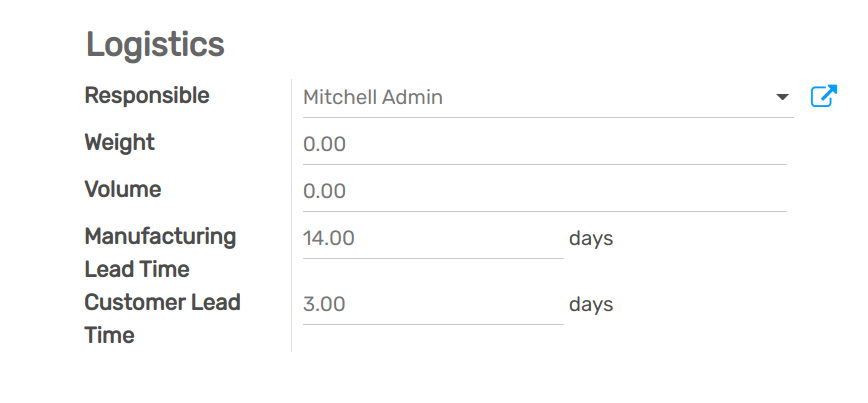

The Customer Lead Time is the time needed for your product to go from your warehouse to the customer place. It can be configured on any product by going to . There, open your product form, go in the inventory tab, and add your Customer Lead Time.

For example, product B is ordered on the 2nd of April but the Customer Lead Time is two days. In that case, the expected delivery date is the 4th of April.

Security Lead Time¶

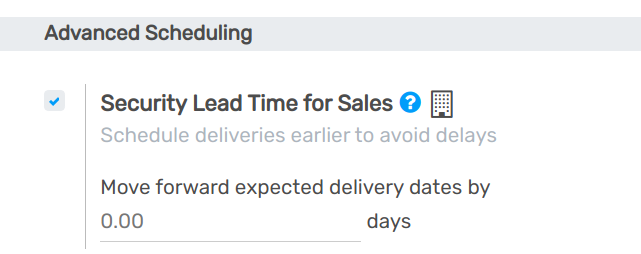

In sales, Security Lead Time corresponds to backup days to ensure you are able to deliver the products in time. The purpose is to be ready shipping earlier in order to arrive on time.

The number of security days is subtracted from the calculation to compute a scheduled date earlier than the one promised to the customer.

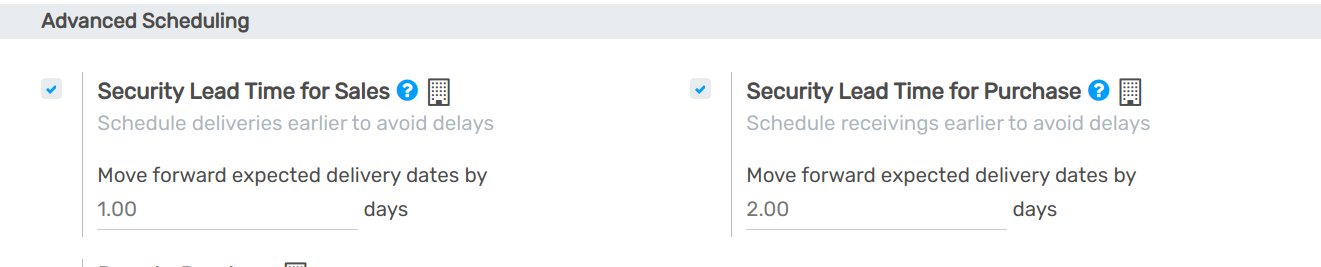

To set this up, go to and enable the feature Security Lead Time for Sales.

For example, product B is scheduled to be delivered on the 6th of April but the Security Lead Time is one day. In that case, the scheduled date for the delivery order is the 5th of April.

Deliver several products¶

In many cases, customers order several products at the same time. Those can have different lead times but still need to be delivered, at once or separately. Fortunately, Flectra can help you handle these cases easily.

From the Other Info tab of your Sale Order, you can choose between When all products are ready and As soon as possible. The first one is to deliver products at once, while the second is to deliver them separately.

For example, products A and B are ordered at the same time. A has 8 lead days and B has 5. With the first option, the Expected Date is calculated based on the product with the most lead days, here A. If the order is confirmed on the 2nd of April, then the Expected Date is on the 10th of April.

With the second option, the Expected Date is calculated based on the product with the least customer lead days. In this example, B is the product with the least lead days. So, the Expected Date is on the 7th of April.

Purchase - Lead Times¶

Supplier Lead Time¶

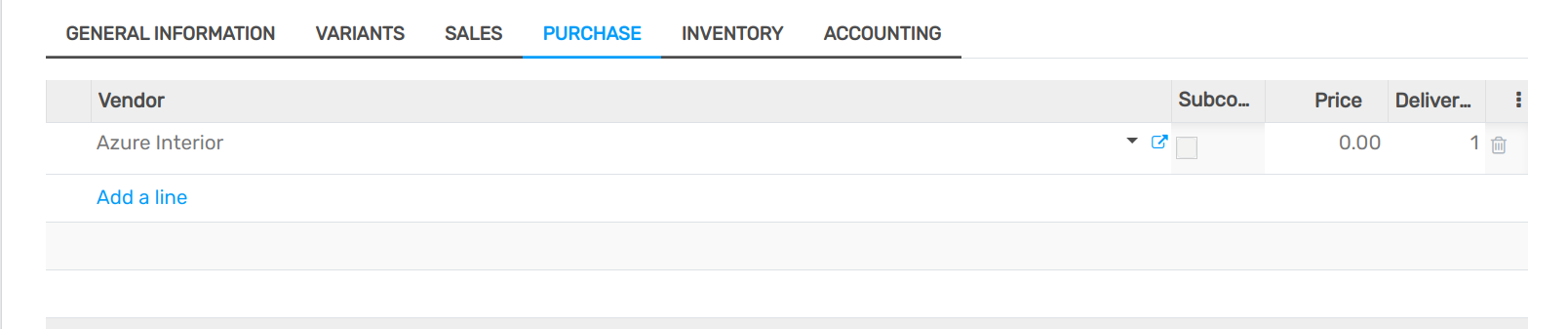

The Supplier Lead Time is the time needed for a product you purchased to be delivered. To configure it, open a product from and add a vendor under the Purchase tab.

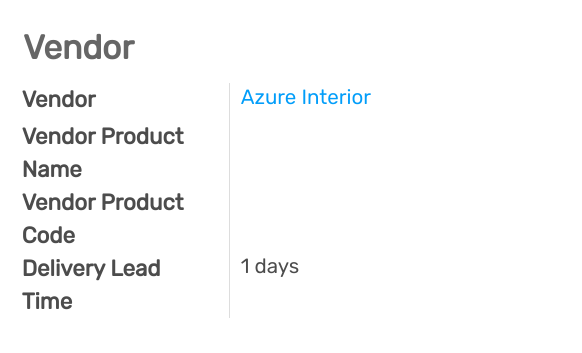

By clicking on Add a line, a new window is displayed. You can specify the Delivery Lead Time there. If done so, the delivery day for every purchase of that product is now equal to Date of the Purchase Order + Delivery Lead Time.

Note

It is possible to add different vendors and, thus, different lead times depending on the vendor.

Security Lead Time¶

The Security Lead Time for purchase follows the same logic as the one for Sales, except that you are the customer. Then, it is the margin of error for your supplier to deliver your order.

To set up Security Lead Time for purchase, go to and enable the feature.

Doing so, every time the system generates purchase orders, those are scheduled that many days earlier to cope with unexpected vendor delays.

Manufacturing - Lead Times¶

Manufacturing Lead Time¶

The Manufacturing Lead Time is the time needed to manufacture the product. To specify it, open the Inventory tab of your product form and add the number of days the manufacturing takes.

When working with Manufacturing Lead Times, the Deadline Start of the MO is Commitment Date - Manufacturing Lead Time. For example, the MO’s deadline start date for an order having a commitment date on the 10th of July is June 27th.

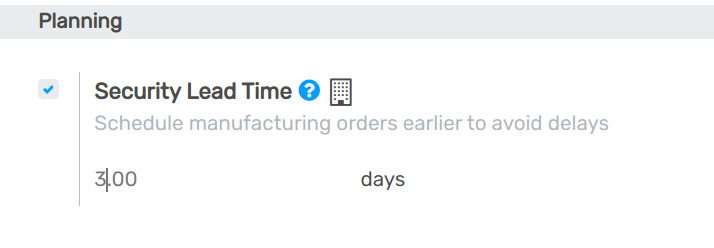

Security Lead Time¶

The Security Lead Time for manufacturing allows generating manufacturing orders earlier to cope with the risk of manufacturing delays.

To enable it, go to and tick Security Lead Time.

For example, a customer orders B with a delivery date scheduled on the 20th of June. The Manufacturing Lead Time is 14 days and the Security Lead Time is 3 days, so the manufacturing of B needs to start at the latest on the 3rd of June, which is the MO’s planned date.

Global Example¶

Here is a configuration:

1 day of security lead time for Sales

2 days of security lead time for Manufacturing

3 days of manufacturing lead time

1 day of security lead time for Purchase

4 days of supplier lead time

Let’s say that a customer orders B on the 1st of September and the delivery date is planned to be within 20 days (September 20th). In such a scenario, here is when all the various steps are triggered.

September 1st: the sales order is created

September 10th: the deadline to order components from the supplier because of the manufacturing process (4 days of supplier lead time)

September 13th: the reception of the product from the supplier (1 day of security lead time for Purchase)

September 14th: the deadline start date for the manufacturing (19th - 3 days of manufacturing lead time - 2 days of security lead time for Manufacturing)

September 19th: the expected date on the delivery order form (1 day of security lead time for sales)